Overview

The following presentation goes over the basics of Value Stream Mapping (VSM). • This presentation uses an imaginary company called “Occamsrazor” to show how Lean principles and simple mathematics are used to create a VSM that will drive the correct project focus.

Occamsrazor Baseline

Occamsrazor is a company that makes the Flimflam and is currently under considerable competitive pressure. • Until recently they had 100% of their market share in their country (X Kingdom) but five months ago three foreign suppliers started importing and selling their version of the Flimflam into X Kingdom. • The three foreign suppliers are selling their version of the Flimflam at a lower price and providing them at shorter lead-times than Occamsrazor. • Occamsrazor has already lost almost 30% of their market share and losing more daily.

Baseline Metrics

The owner of Occamsrazor reviewed the competition and determined these baseline metrics.

To regain market share the owner of Occamsrazor set these company goals:

- Reduce lead-time to 8 days

- Reduce price to 30

- Maintain profit margin

- Be able to handle total market volume

VSM Data – Takt Time

Occamsrazor hired a Lean consultant to help them review their company and put in place improvement plans. • Current Flimflam volumes where at 30/day but because Occamsrazor hoped to regain most of their market share they set their goals at the total market of 42/day.

- Occamsrazor’s employees work one shift of 8 hours with a lunch break of 1 hour so:

- Total work time is 8 – 1 = 7 hours or 420 minutes

- Takt time equals the rate at which Occamsrazor is currently creating Flimflams to meet their current customer demands:

- 420min/30 flimflams = 14 min/flimflam

- Takt time, the rate at which Flimflams would need to be created to meet the total market, would be: 420min/42 flimflams = 10 min/flimflam

Other Key Metrics

- Occamsrazor has 6 full time employees that make Flimflams.

- Labor cost per employee is 13/hour.

- Material cost per Flimflam is 13.

- The total order rework and scrap rate is 48% (ie Rolling Through-put Yield or RTY=48%).

- Total system WIP is equal to 360 Flimflams (As per physical count)

VSM Basics

Before we get started lets take a look at some basics behind making a VSM.

- This project example is intended to show how Lean concepts can be applied in either manufacturing or the office. Although each VSM will be unique, as they focus around different company goals and process characteristics, they all have some similarities.

A VSM has two key shapes:

Process Step

Queue Step

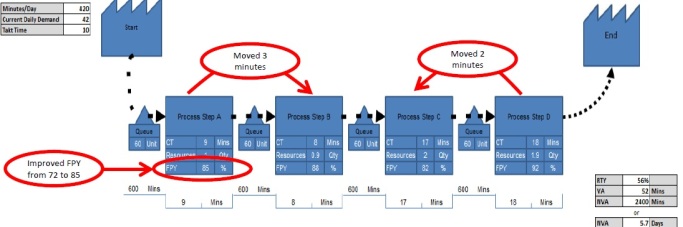

Current State VSM

Next we will see the Current State VSM for Occamsrazor. Take some time reviewing this map and note that resources, Work In Process (WIP) and Lead-Time match the current state metrics at Occamsrazor. When you make a Current State VSM it takes some skill and time to make sure it matches reality. A Current State VSM that does not match the actual current state is useless and must be corrected before proceeding.

Key Observations

Process Step A has less resources than needed to keep up with demand. Discussion with the people on the line show that many times the person from B is helping out at A. The person at B does not have the proper training to be working at A and is contributing to the low FPY at A. Process Steps B, C and D have more resources than needed.

Current Profit Margin

- Labor cost per employee is 13/hour

- With 7 hours per day and 6 resources at 30 Flimflams per day = 7×6/30 = 1.4 hours

- Labor cost per Flimflam = 1.4 x 13=18.2

- Material Cost per Flimflam = 13

- Total Cost per Flimflam = 18.2+13=31.2

- This assumes no lost material for scrap or rework

- Profit Margin = (36-31.2)/31.2 = 15%

Current State-Takt of 10

- Since the company goal is to regain the total market of 42 Flimflams per day the Future State needs to take into consideration these increased volumes

- 42 Flimflams per day make at Takt Time of 10 minutes per unit.

- Before going forward lets take a look at how the Current State VSM would look if we plugged in the Takt time of 10.

Potential Projects

Potential Future State

Future Profit Margin

(please note red from goals set earlier)

- Labor cost per employee is 13/hour

- With 7 hours per day and 6 resources at 42 Flimflams per day = 7×6/42 = 1 hour

- Labor cost per Flimflam = 1 x 13=13

- Material Cost per Flimflam = 13

- Total Cost per Flimflam = 13+13=26

- This assumes no lost material for scrap or rework

- Profit Margin = (30-26)/26 = 15%

Comments

- This potential Future State will meet the goals of 42 Flimflams per day and an 8 day lead-time.

- It will also meet the product price reduction to 30 while maintaining the profit margin.

- The type of projects selected need to be realistic. An experienced operations and supply chain project manager needs to facilitate project selection so that the Future State is achievable.

- Before any projects are started their expected results need to be plugged into a Future State map to confirm that company goals will be met.

- This is a very simple VSM. Forked flows, feeder lines and mixed model make more difficult modeling. Getting Value Stream Mapping Training is important for those more complicated models. Also Free Value Stream Mapping Software is very helpful.

Please Post Comments or Questions Here.

Great mini-lesson. Thanks!

LikeLike

Interesting example. One question pops to mind though – how do you calculate the WIP? My calculated WIP comes to 360 whereas the example quotes 320. So I am puzzled.

LikeLike

Derek,

Thanks for catching this. I have updated the website to indicate 360 units WIP. The WIP is from a physical count. The through-put time is calculated as:

(360units X 14 min/unit) / (420min/day) = 12days. For others looking at this, 14 min/unit is the production rate. Production is going slower than the 10 min/unit takt time.

LikeLike